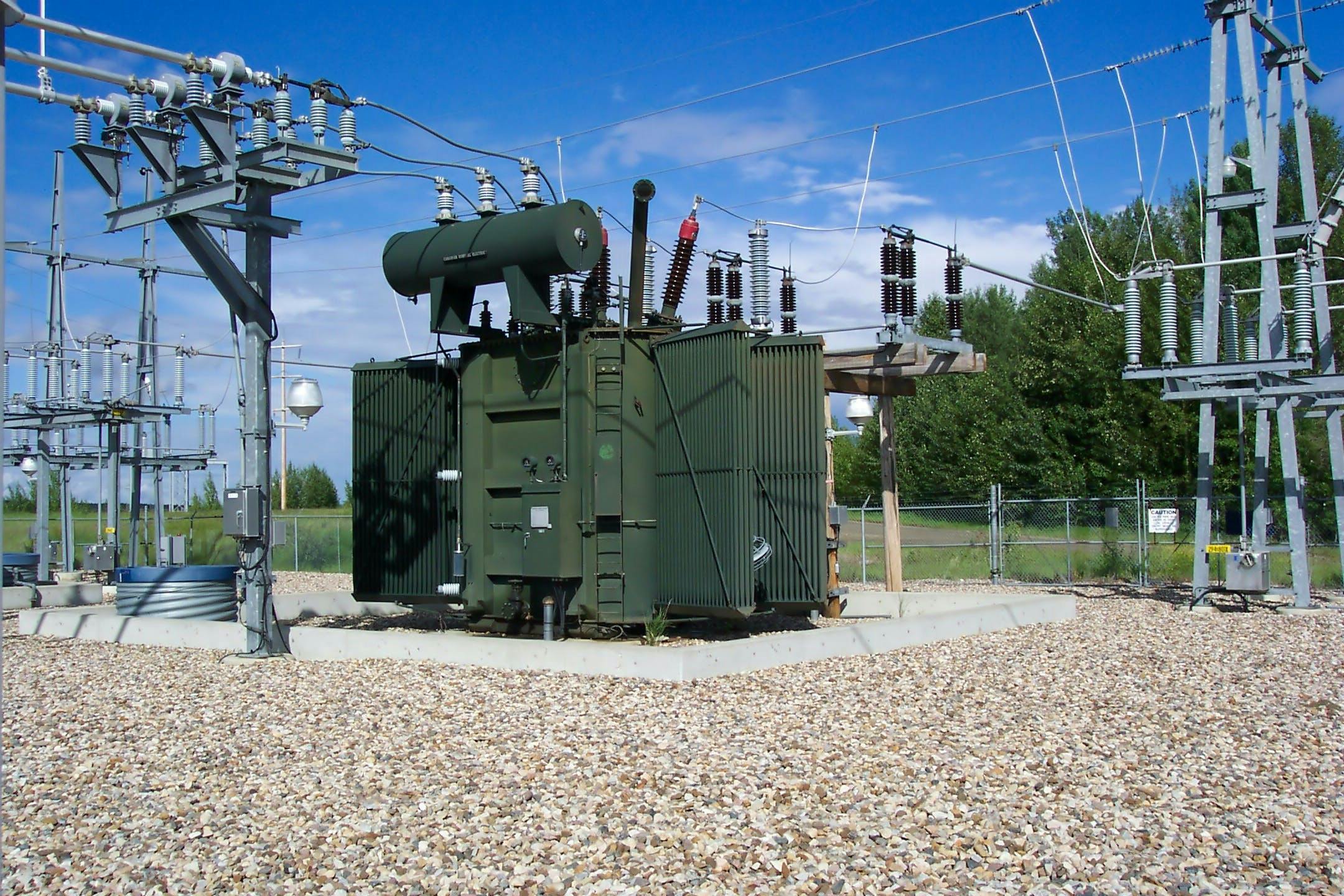

Transformers are amongst the most operation-critical assets on any HV site, and keeping them in good condition is vital.

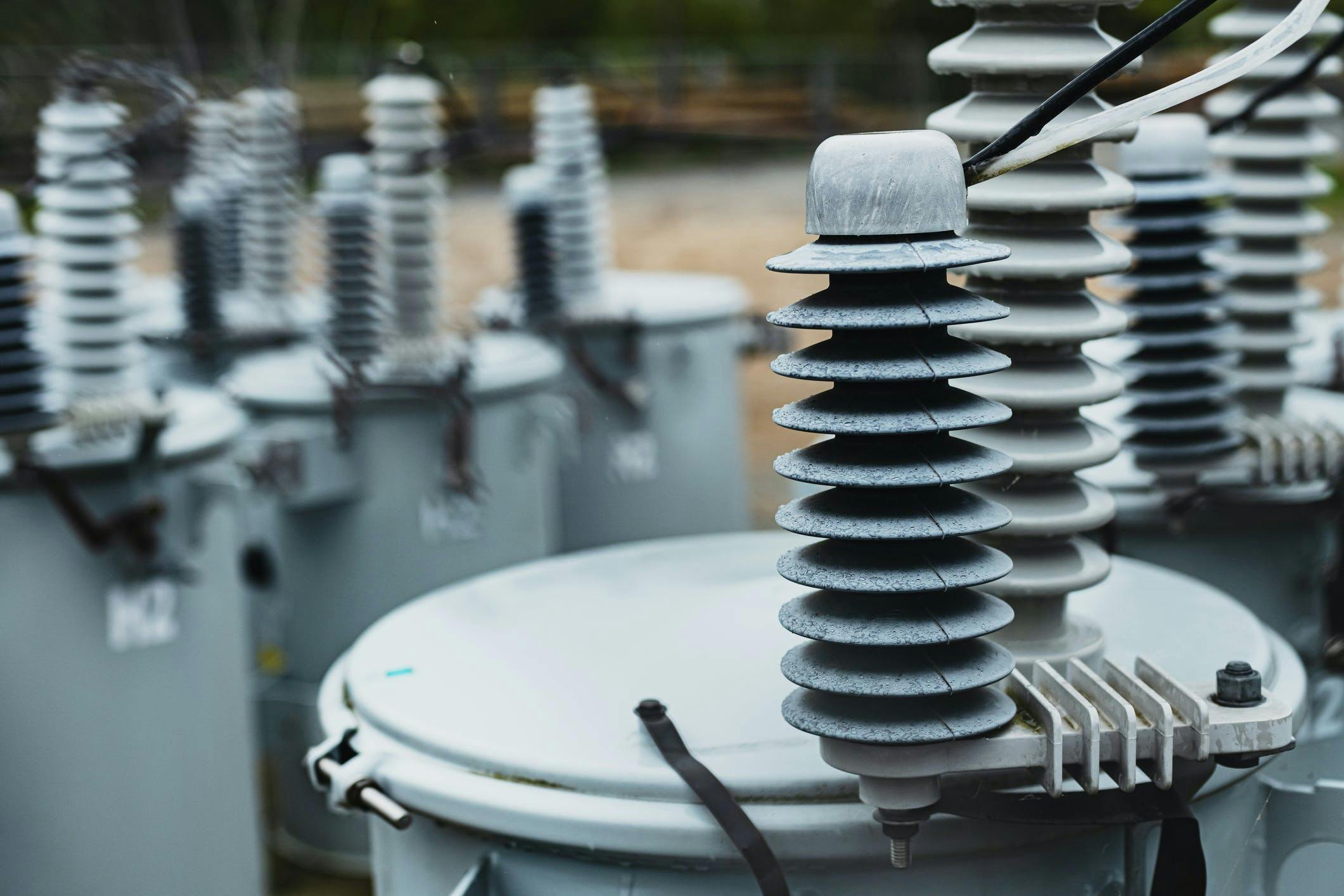

In oil-filled transformers, gas bubbles in the oil, voids or gaps in the paper or pressboard insulation and high voltage partial discharge in the bushings and tap-changers can all contribute to the failure of the transformer. In dry-type transformers, surface tracking and voids in the insulation are the most common causes of problems in transformer insulation.

At Monitra, we have a range of testing and monitoring solutions that can help to detect the development of underlying defects and assess the insulation condition of your transformers, increasing safety and avoiding unplanned outages.

To find out more about our range of solutions for transformers, contact us today via our online form.

Utilising the Kronos Spot Tester, our team of test engineers can perform On-line and Offline testing on a schedule that suits you, whether your transformers are connected to the grid, in commissioning stages or offline during scheduled outages.

To see where we are exhibiting and to engage with our educational resources, see further information below.

To read more on the applications of our testing and monitoring solutions for transformers, take a look at our library of case studies below.